Mechanical Engineering Intern – Resilience, Inc.

What?

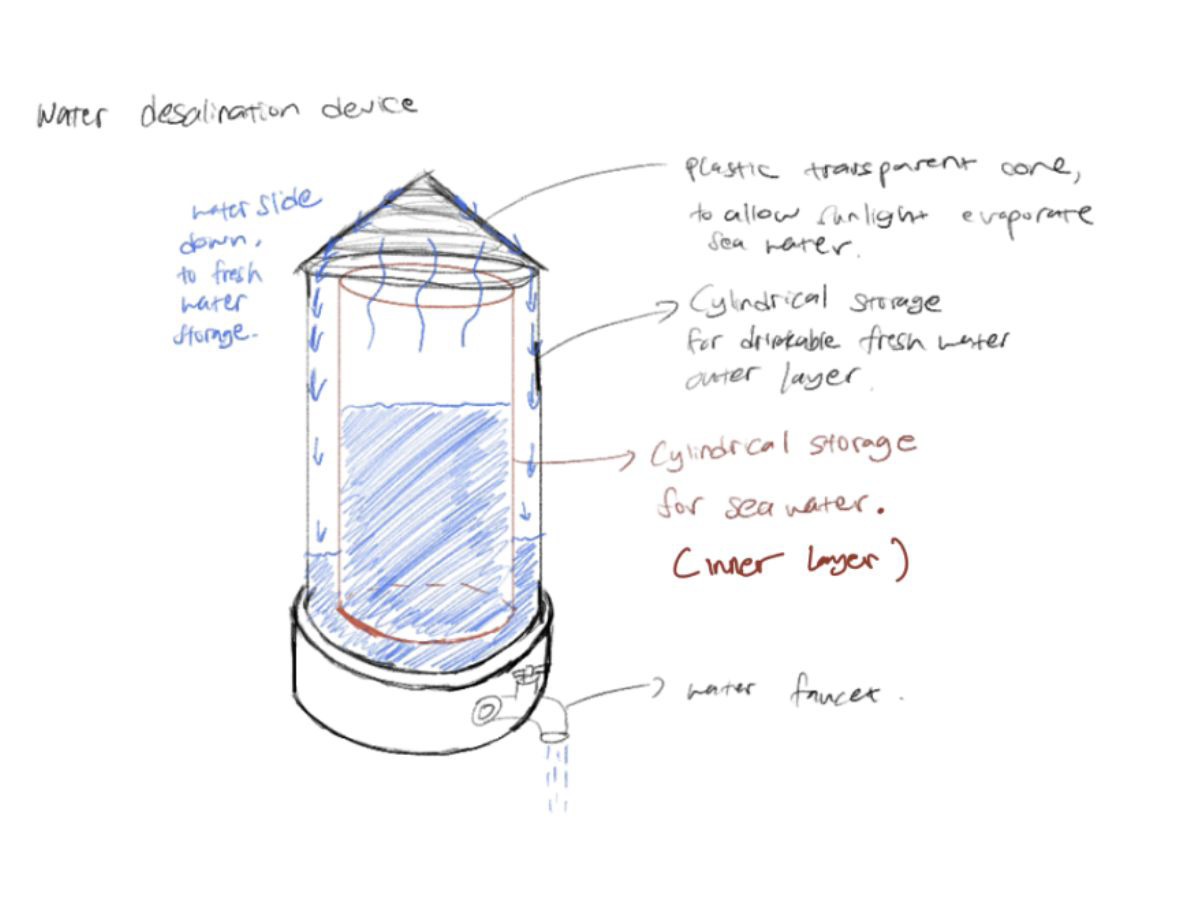

- SALI is a passive solar desalination device that converts saltwater into clean drinking water using sunlight and a vacuum-assisted system—without electricity or filters.

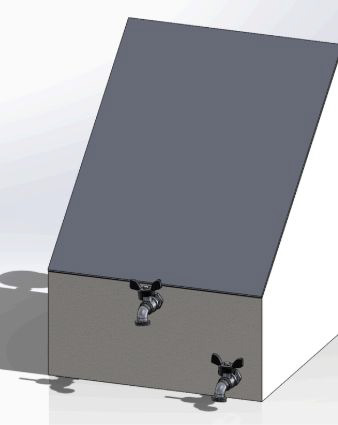

- The first prototype was a box design that proved the core concept but had limitations in heat distribution, sealing, and scalability. The redesigned cylindrical version improves thermal efficiency, vacuum sealing, and manufacturability, with clearer flow paths for saltwater input, brine discharge, and freshwater collection.

How?

- SALI uses the natural evaporation–condensation cycle, enhanced by solar heating and reduced pressure.

- Saltwater enters the chamber, a vacuum pump removes air to lower the boiling point, and sunlight heats the water to accelerate evaporation. Freshwater condenses on the inner surface and flows into a clean reservoir, while concentrated brine exits through a separate outlet.

- The entire system was modeled and refined in SolidWorks to optimize geometry, thermal behavior, and sealing performance.

Result?

- The cylindrical SALI prototype delivers higher evaporation rates and more uniform solar heating, and significantly Improved vacuum retention compared to the first version. It is easier to manufacture, more reliable in operation, and better suited for real-world, off-grid desalination applications.

Mechanical Engineering Intern – Heidelberg Materials

What?

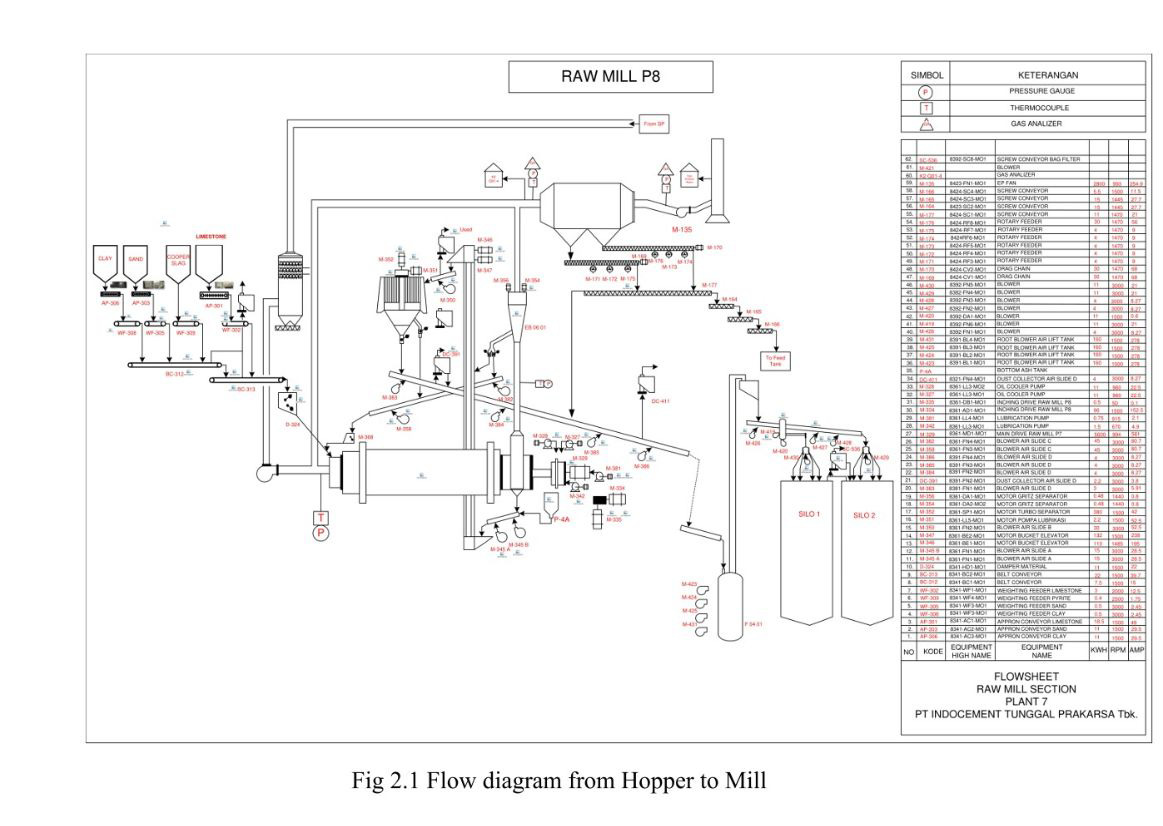

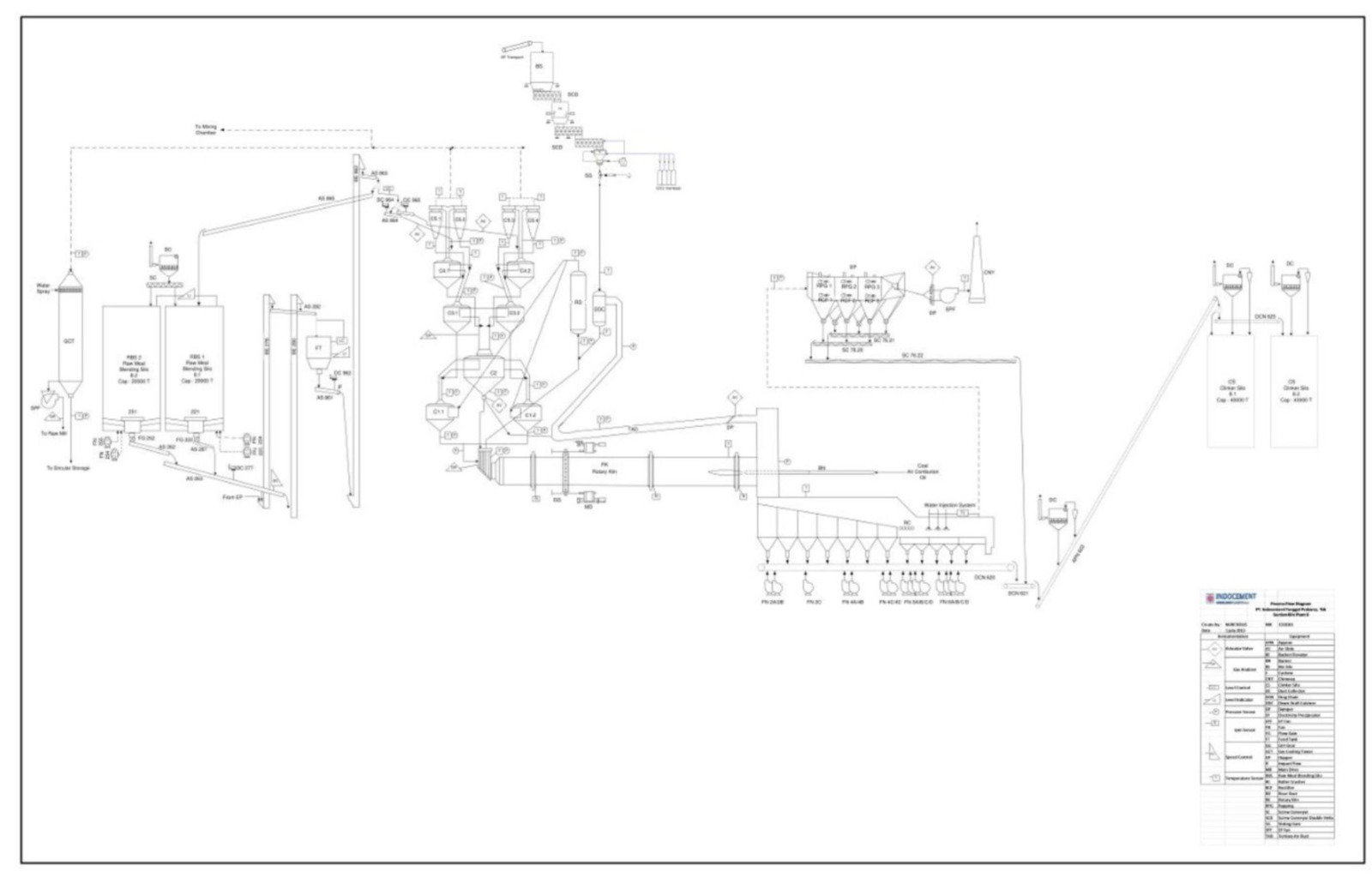

- Worked as a Mechanical Engineering Intern at PT Indocement (Heidelberg Materials), supporting maintenance and reliability operations for the Raw Mill GA 45 VSD air compressor—critical to the plant’s bag filter system.

How?

- Created clear technical documentation to standardize maintenance procedures and improve equipment reliability.

- Used Maximo to inspect, lubricate, and replace mechanical components, ensuring proper scheduling and traceability.

- Conducted on-site diagnostics to identify early signs of wear and prevent unplanned downtime.

Result?

- Improved compressor reliability and extended component lifespan.

- Helped maintain continuous Raw Mill bag filter operation, reducing the risk of production interruptions.

- Delivered maintainable documentation still used by the maintenance team after the internship.

Structures Engineer – Washington Tunneling

What?

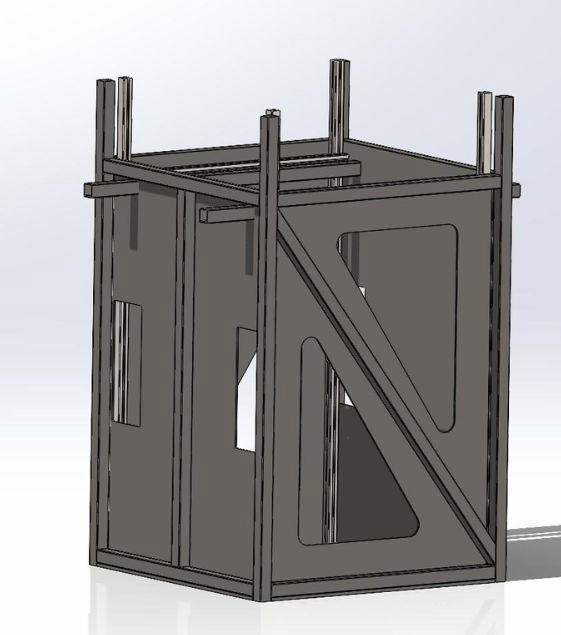

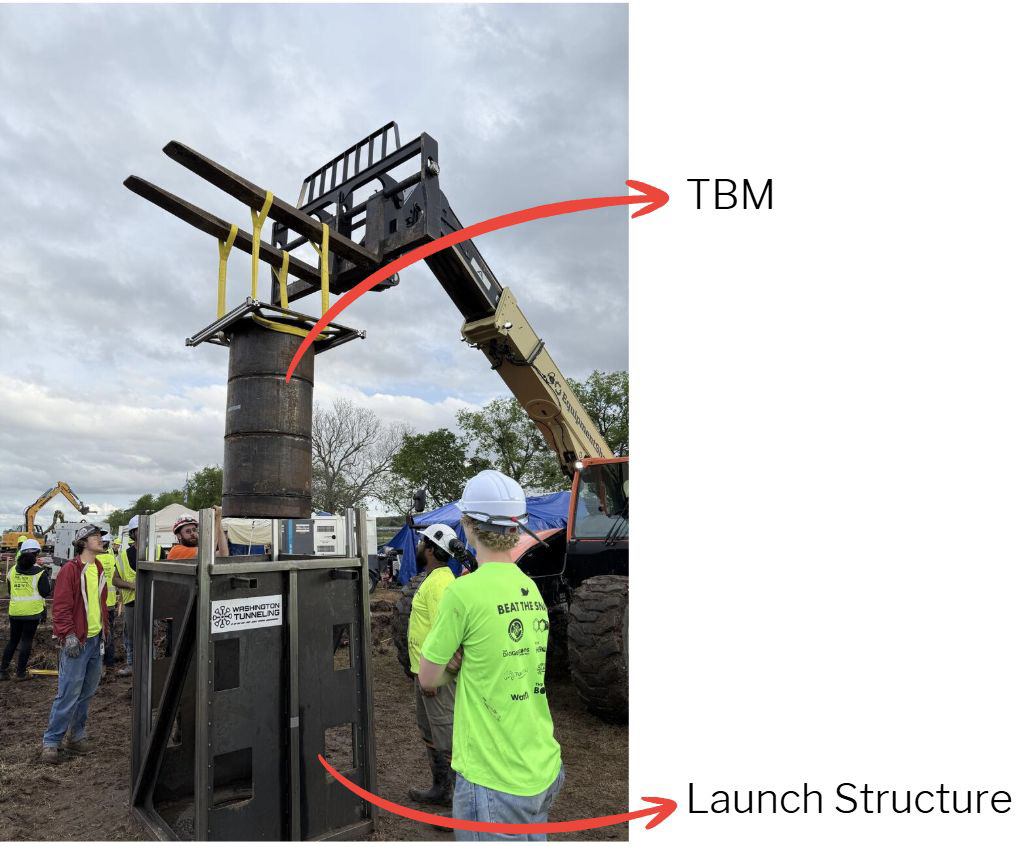

- Designed and built key components for a scaled-down Tunnel Boring Machine (TBM) as part of the 2025 Not-A-Boring Mini Competition. My work focused on designing the vertical launch structure that supports the TBM’s weight and torque during drilling.

How?

- Created and optimized SolidWorks models for launch-structure components, improving manufacturability and structural reliability.

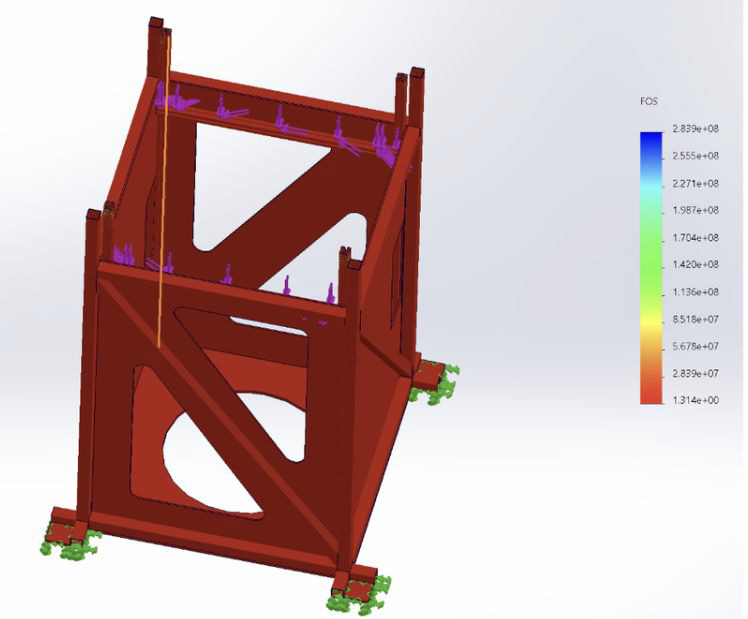

- Performed FEA to evaluate combined bending, shear, and torsional stresses, addressing stress concentrations around bolt holes.

- Refined the cross-sectional geometry to increase the moment of inertia, reducing bending and keeping von Mises stress safely below yield.

- Supported hands-on fabrication and assembly using welding, grinding, and machining techniques.

Result?

- Delivered a stronger, safer, and more efficient launch structure that outperformed previous iterations.

- Contributed to the team securing 1st place in the Cutterhead Mini Competition and successfully demonstrating the full TBM at the final event.

Competition Video (on-site)

ME123 Final Project – University of Washington

What?

- Designed a household water filter pitcher in SolidWorks, inspired by Brita-style products, with a focus on usability, manufacturability, and clean consumer-product aesthetics.

How?

- Modeled a push-button lid, internal reservoir, and ergonomic handle using advanced CAD techniques including lofted surfaces, hinge mates, component patterns, and transparent rendering.

- Applied design-for-manufacturing principles to ensure all components could be injection-molded and assembled efficiently.

- Iterated geometry and proportions to balance function, comfort, and visual appeal.

Result?

- Delivered a complete, fully-assemblable CAD model demonstrating strong consumer-product design skills.

- Achieved a refined, functional pitcher concept with realistic features and manufacturable geometry suitable for further engineering development.

Undergraduate Researcher – UW Computational Fluid Mechanics Lab

What?

- Investigated the interaction of Taylor length-scale droplets with homogeneous shear turbulence as part of advanced multiphase flow research.

How?

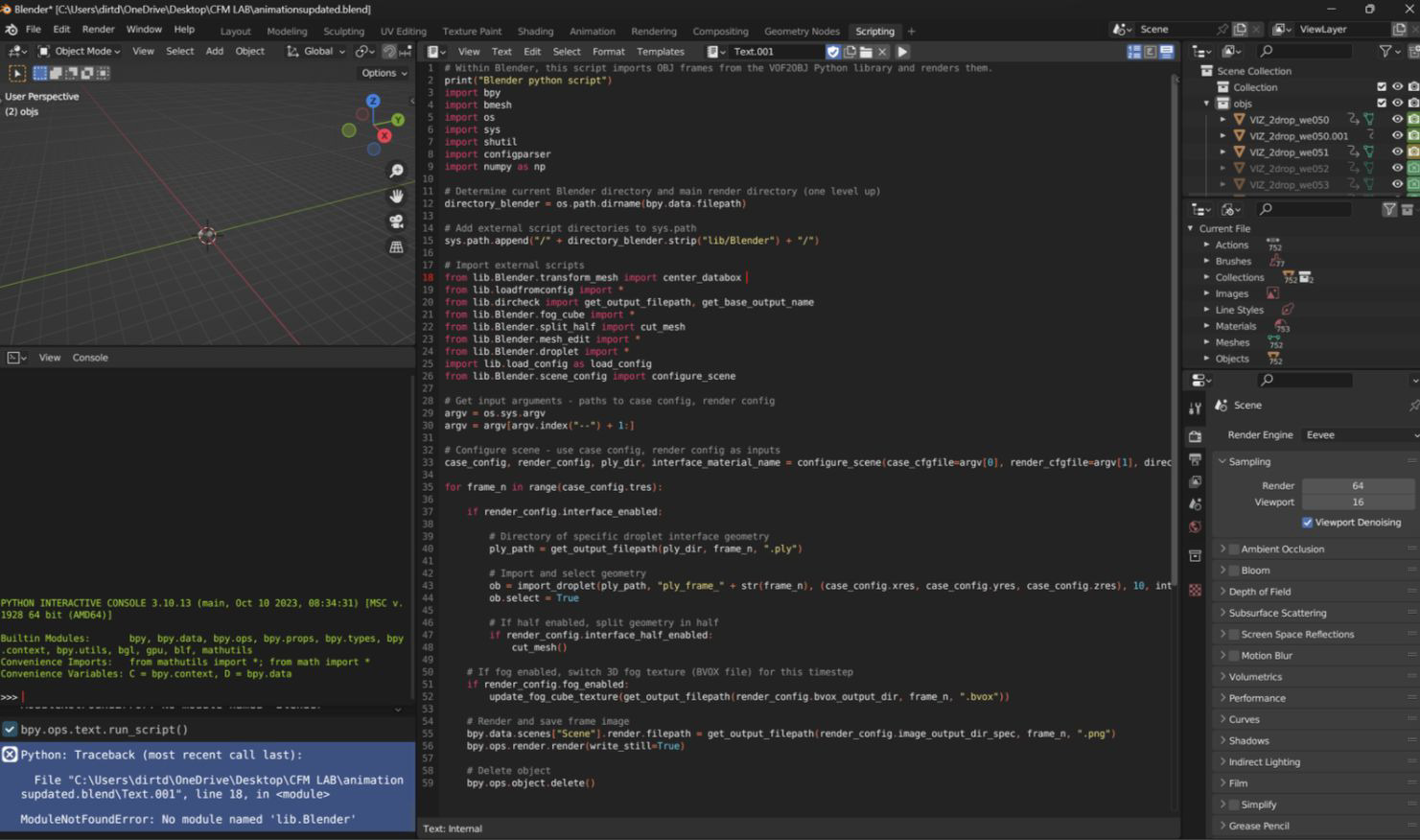

- Ran direct numerical simulations (DNS) on UW’s Hyak Klone high-performance computing cluster, handling large-scale .h5dns data sets.

- Developed Python scripts to automate post-processing and extract velocity, pressure, and vorticity fields from DNS outputs.

- Created high-fidelity 3D visualizations in Blender, using camera tracking, cloudscape environments, and physically accurate material properties to replicate droplet optical behavior.

- Collaborated on workflows outlined in the CFM-DNS repository and onboarding documentation to ensure reproducibility and efficiency.

Result?

- Produced visualizations that directly supported the research publication “On the Interaction of Taylor Length-Scale Size Droplets and Homogeneous Shear Turbulence” (J. Fluid Mech., 2023).

- Contributed to advancing the understanding of droplet–turbulence energy transfer mechanisms, including modulation of turbulence kinetic energy through droplet deformation, breakup, and coalescence.

- Strengthened the lab’s visualization pipeline, making results more accessible for publications, conference presentations, and the Gallery of Fluid Motion.

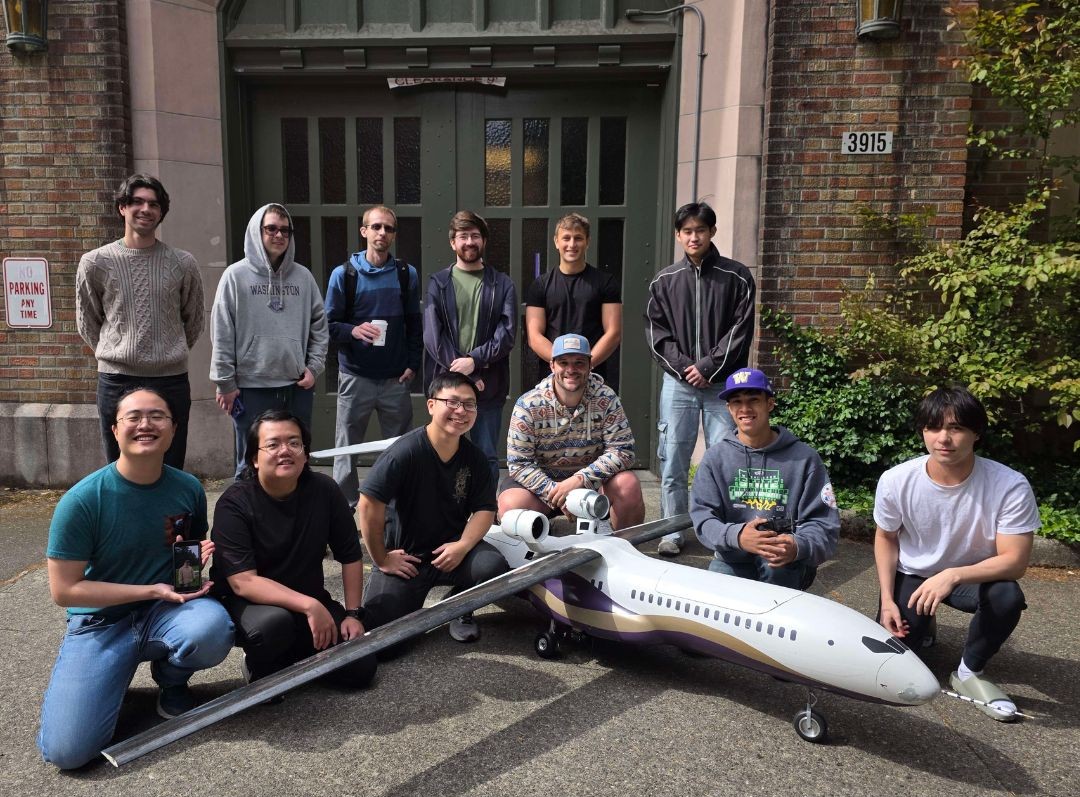

AA Capstone – University of Washington

What?

- Refurbished the Structural Health Monitoring System (SHMS) on AeroTEC’s 2011 UAV to assess whether in-flight loads exceeded structural limits by comparing live strain data to analytical predictions.

- The project supported training of AeroTEC’s machine-learning model under FAA-compliant flight-test standards.

How?

- Installed and aligned all servo actuators, ensuring full control-surface deflection and reliable telemetry.

- Calculated maximum landing impact loads using sink-rate and kinetic-energy analysis to define worst-case scenarios.

- Mounted and positioned the onboard camera system for unobstructed structural-response monitoring.

- Integrated and wired strain gauges into the airframe to enable real-time load capture during ground and flight tests.

Result?

- Restored full SHMS functionality, enabling accurate comparison of in-flight loads to structural limit predictions.

- Improved data quality for AeroTEC’s ML-based structural-response model.

- Supported safe, FAA-compliant testing and expanded reliability of the UAV’s flight-test instrumentation.

Contact Me

Contact Me

Send an Email

Send an Email

Location

Location